Truck Stop / Service Station Water and Sewage Treatment Plant with Irrigation System

Customer: Puma / Chevron

Location: Traveston, QLD

Case Study ID: CS-121

Date: November 2020

Download PDF Version >>

Overview

After a successful tender process Dowdens Pumping & Water Treatment was engaged to design, construct and commission a new, Sewage Treatment Plant, Potable Water Treatment Plant and Treated Effluent Irrigation system.

Description of Commercial Roadside Facility (CRF)

The design vision for the site is to create a safe, visually appealing and convenient destination for drivers to rest refuel-recharge. The proposed development has been designed to improve driver safety outcomes by enticing drivers to break their journey, rest-refuel and recharge by providing TMR users with 24/7/365 rest-refuel-recharge amenities and no obligation driver rest areas.

The proposed development area is approximately 4.474ha, Traveston QLD. The site location relative to both Brisbane and the Fraser Coast region (2 hours travel either way), makes it ideally located to support the State’s overarching objective to improve road safety outcomes by providing facilities that encourage drivers to break their journey and avoid driver fatigue.

-

Commercial Facility:

(1365m2): incorporating a service station, food and drink retailers, an information centre, food forecourt with external dining and kids play area, free of charge public amenities and a truck driver’s lounge/ amenities area separate to the general public area of the main building.

-

Driver Rest Areas:

For heavy vehicles (856m2) and light vehicles/ cars with caravans (4,860m2).

-

Light Vehicle Fuel Canopy:

Offering sixteen (16) dispensing positions for retailing of ULP, E10, premium fuel grades of fuel, Diesel as well as air/water facilities.

-

Truck Fuel Canopy:

Offering eight (8) dispensing positions for retailing Diesel, Premium Diesel, Biodiesel blends and Adblue.

-

Future Electric Vehicle (EV) Charging Station Area:

Allocation of four (4) spaces to enable future fast-charging infrastructure.

-

Parking facilities:

For light vehicles (121 spaces), cars with trailers and caravans (13 spaces), buses/coaches (6 spaces) and heavy vehicles up to 26m b-double (24 spaces).

The Problem

The location of the commercial roadside facility did not allow for connection to the local council water services. Therefore, all potable water and sewage treatment plants and associated equipment would need to be located onsite.

Our Solution

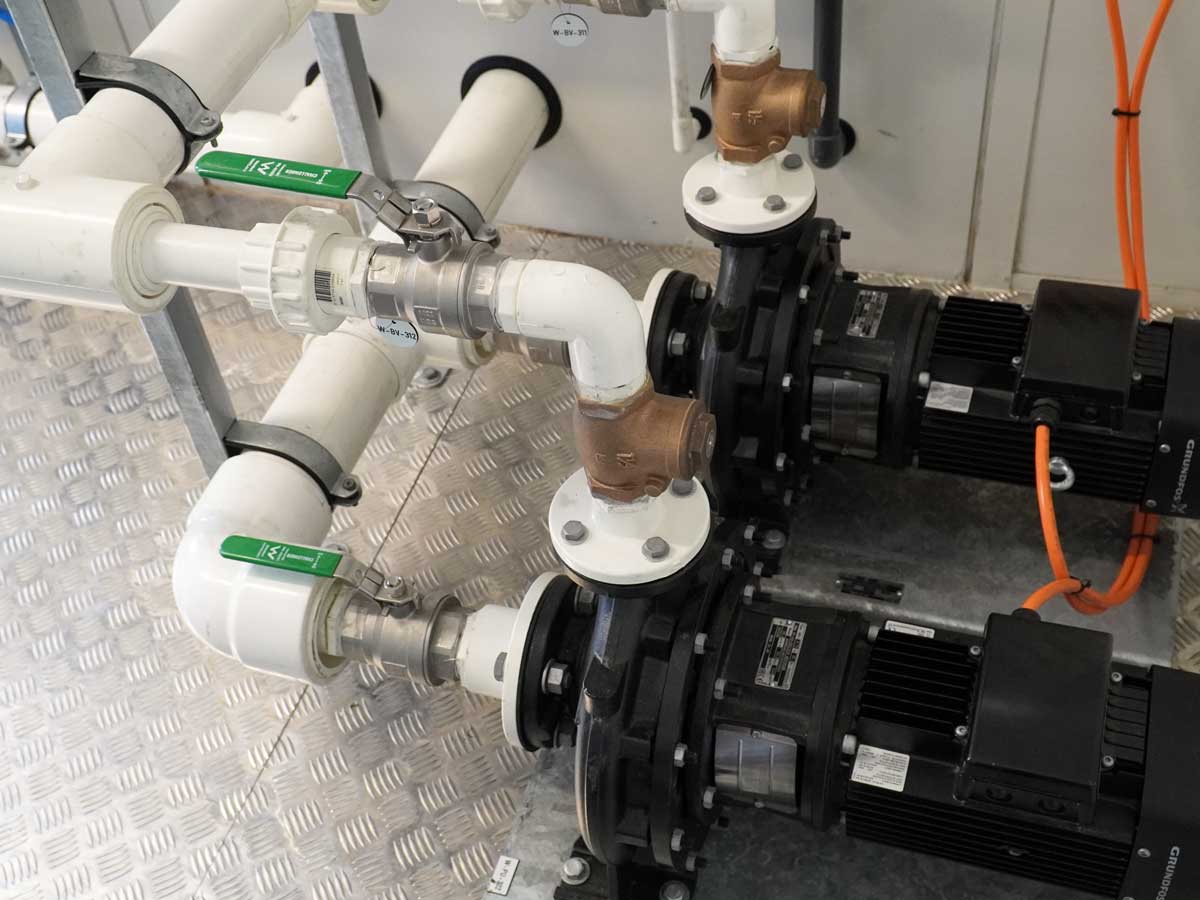

The Dowdens EPC ( Engineering, Construction and Procurement ) team designed:

- A modular containerised sewage treatment plant with all major process equipment installed within a 40-foot container including process tanks, membrane bioreactor, pressure pumps, dosing pumps, electrical and electronic control systems.

- 2ha irrigation system including a 170kl Kingspan panel storage tank, irrigation pumps and control system.

- A Modular containerised water treatment plant with all major process equipment installed within a 20-foot container including filters, pressure pumps, dosing pumps, electrical and electronic control systems. The container included safety handrails to allow easy access for maintenance purposes to sewage treatment equipment and components located on top of the container.

- Both the water & sewage treatment systems can be operated remotely via the mobile-friendly web-based interface on a NextG network.

Key Components

Sewage Treatment Plant:

- 6kl pump station

- 40-foot containerised Membrane Bioreactor

- 2 x 45kl Nu-Tank Poly Industrial UV stabilised tanks

- Roto Balance Transfer Pumps

- Anoxic overhead mixer with stainless steel wetted parts

- RAS and recycle submersible vortex pump with mag-flow meter

- 2 x Aeration/membrane air-sour blowers

- Fine bubble diffusers

- German-made Bio-Cel membranes

- Positive displacement, reversible flow VFD controlled permeate pumps

- Siemens mag-flow meters for instantaneous and totaliser flow readings

- 5 x Grundfos chemical dosing pumps for chlorine and citric acid, caustic soda, sucrose, PAC anoxic pH adjustment system.

- 4 x 110L chemical drums (chlorine, caustic coda, sucrose and PAC) with side measurements

- Effluent chlorine dosing system

Water Treatment Plant:

- 20-foot Containerised system

- Activated Media Filters

- Activated Carbon Filters

- Feed & Backwash Pumps

- Ultraviolet disinfection system

- Chemical disinfection system

- Recirculation pumps

- Instrumentation (Level, turbidity, pH, free chlorine and flows)

Irrigation System:

- 170kl Kingspan effluent panel tank

- Grundfos Vertical Multi-stage variable speed pumps

- Effluent rated poly pipe, valves, fittings and fixed sprinklers.

- 2 ha irrigation area with sprinklers to produce heavy droplets with low trajectory nozzles

- 18 station irrigation controller

Project Design Philosophy

The design was been based on the following criteria:

- Cost Effectiveness

- Simple Operation

- Reliability and Low Maintenance

- Ease of Installation

- Low Energy Consumption

- Water QualityBrands used in this project